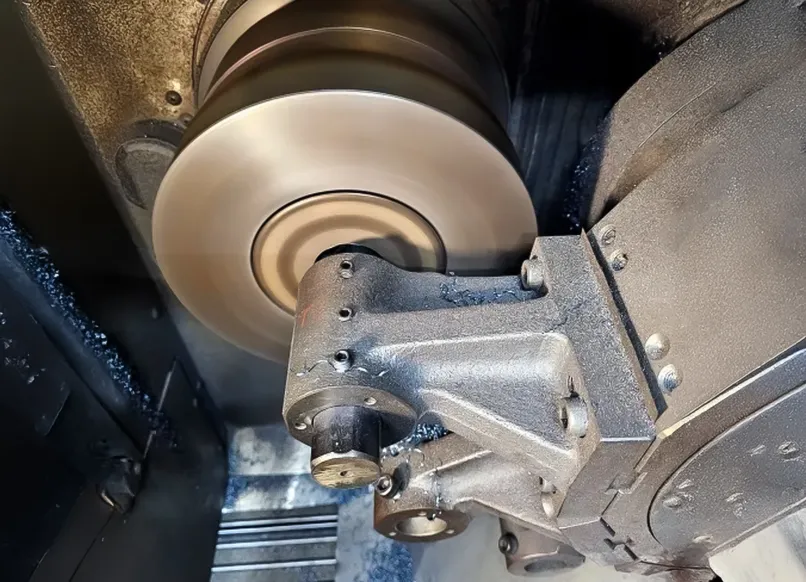

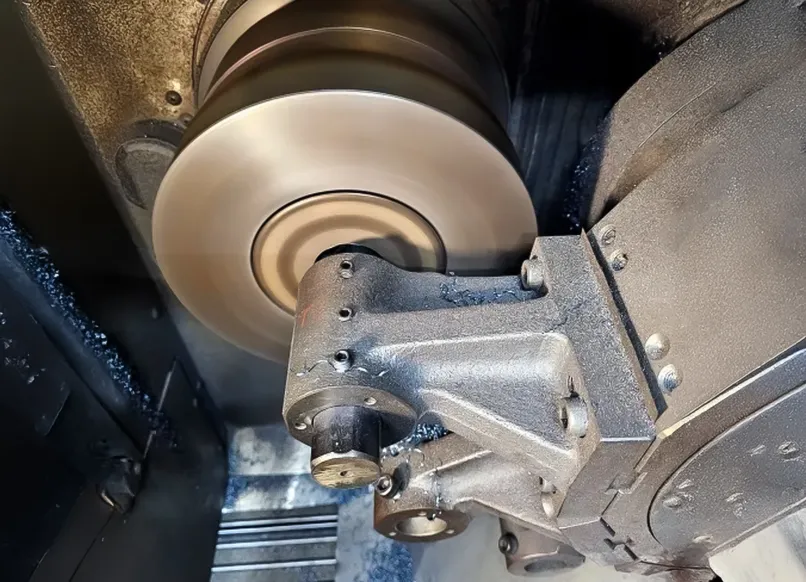

CNC Machining

Baxter Machine offers advanced CNC machining for precise, efficient, and repeatable manufacturing. Ideal for complex parts and tight tolerances, ensuring top-quality results every time.

Baxter Machine excels in precision grinding, CNC machining, and high-volume component production, specializing in automotive orders over one million units.

Baxter Machine offers advanced CNC machining for precise, efficient, and repeatable manufacturing. Ideal for complex parts and tight tolerances, ensuring top-quality results every time.

Baxter Machine Engineered for precision grinding, Baxter delivers unmatched accuracy and performance—perfect for high-tolerance applications and flawless finishes.

Baxter Machine specializes in high-quality component production, delivering consistent precision and durability for a wide range of industrial applications. Reliable parts, built to perform.

Precision-Driven Equipment for Unmatched Performance. Engineered for reliability, accuracy, and efficiency. Trusted by industries for consistent, high-quality results.

Equipped with advanced twin and single spindle CNC lathes from Fuji, Mori Seiki, Okuma & more—most with gantry loaders for automation. Built for high-precision, high-volume production with consistent, reliable performance. Ideal for complex parts and tight tolerances across industries.

Our CNC milling capabilities feature high-performance machines from Haas and Fadal, including vertical and horizontal centers with twin pallet systems and 4th axis support. Designed for precision, efficiency, and repeatability, these mills are ideal for producing complex parts with tight tolerances across a wide range of applications.

Our secondary operations are supported by advanced deburring systems, hydraulic presses, washers, and bore finishing equipment. From vibratory and rotary deburring to custom cleaning solutions and precision bore finishing, we ensure every component meets the highest standards of finish and functionality before delivery.

Our inspection capabilities feature advanced tools like CMMs, surface finish meters, and form measurement systems from trusted brands such as Taylor-Hobson, Hexagon, Mitutoyo, and Brown & Sharpe. These precision instruments ensure every part meets strict quality and dimensional standards for reliable, consistent performance.

Our fully equipped tool room includes engine lathes, Bridgeport mills, honing machines, welders, and surface grinders. With precision readouts and versatile machining tools, we support in-house maintenance, prototyping, and custom tooling to ensure seamless production and quick turnaround times. This in-house capability allows us to maintain full control over quality and flexibility throughout the manufacturing process.

Discover precision engineering and cutting-edge technology. Designed for performance, built for reliability.

See what our satisfied customers have to say about their experience!

Baxter is a very easy company to do business with. The hard gauges that Baxter has developed internally, provide a high level of assurance that the parts are being machined to customer specifications every time.

Sales Manager

Baxter Machine has provided us exceptional machining and grinding services for some very challenging automotive transmission components.

Process Engineer

Through our commercial relationship, Tremec has received outstanding service and quality from Baxter Machine. Baxter has always been willing to provide engineering and development support to our company.

Corporate Purchasing Manager

Working with Baxter Machine has been an outstanding experience! Their attention to detail, quality craftsmanship, and commitment to delivering top-notch industrial machinery exceeded our expectations.

Operations Manager

103 N. Horton St., Jackson, MI 49202, United States

seth.baxter@baxtermachine.com

+1 517 782 2808