How to Control Distortion in Machining: Heat Treat, Grinding & Process Planning

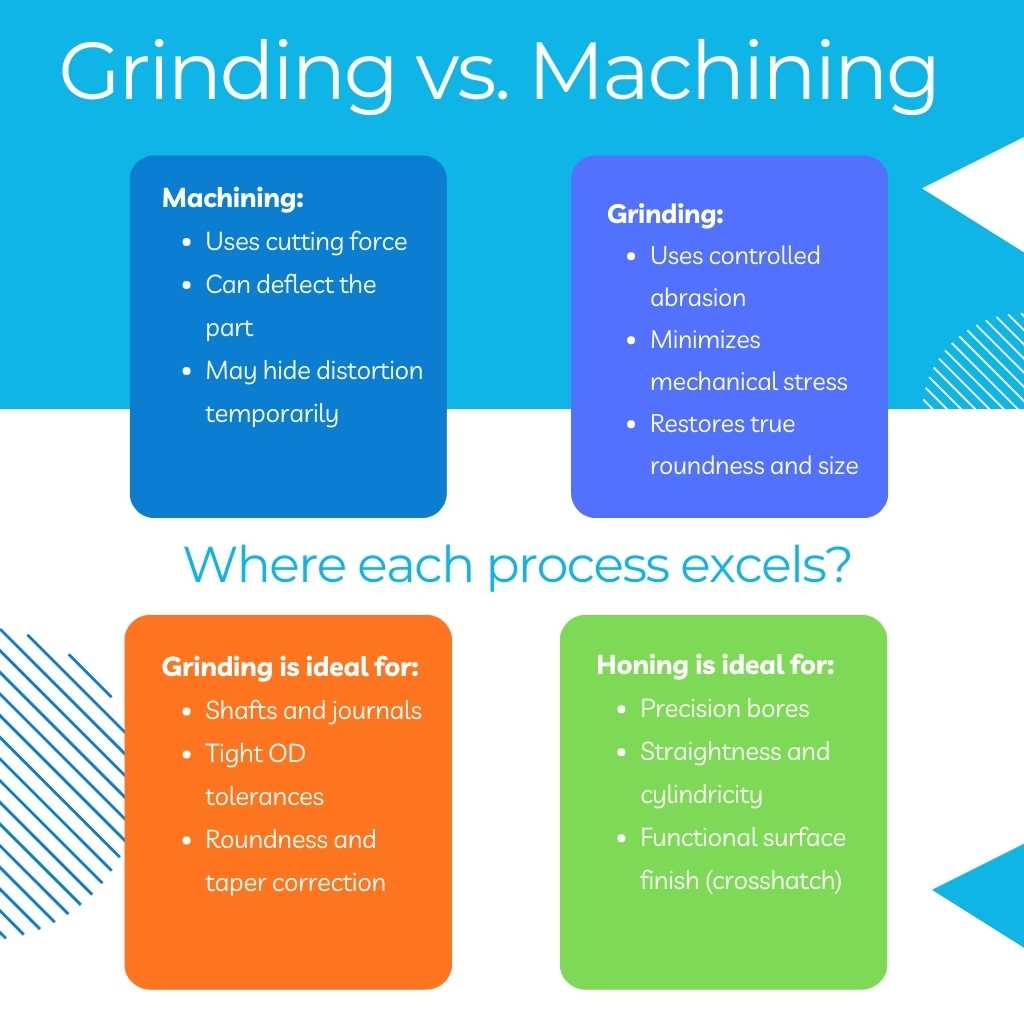

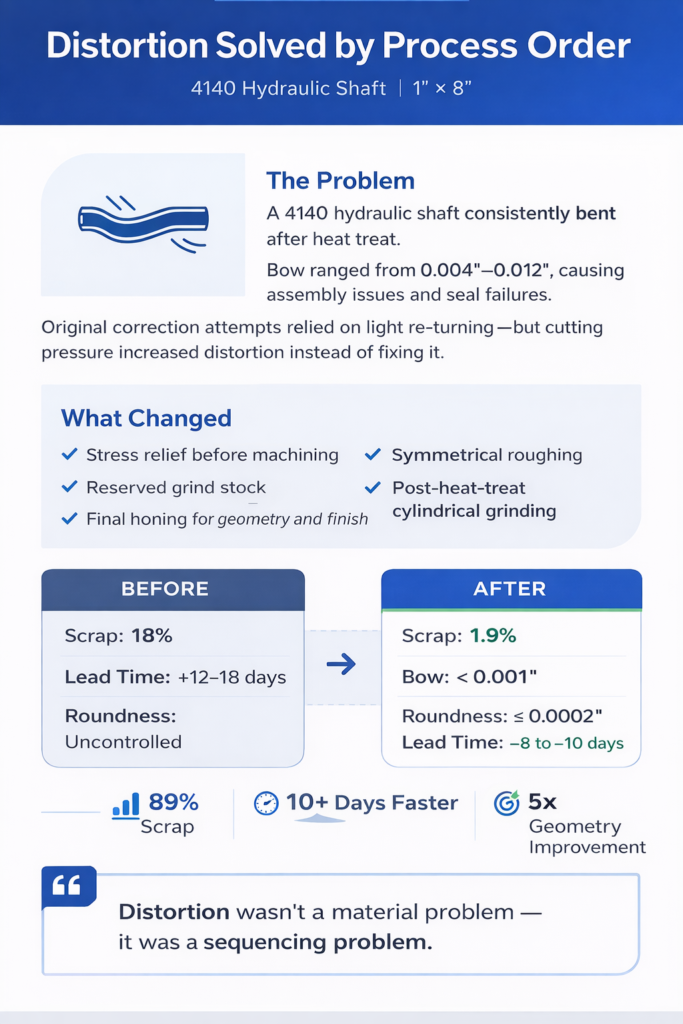

Machining distortion is not random; it stems from mechanical, thermal, metallurgical, and clamping stresses revealed during machining or after heat treat. Heat treat is often the primary cause, with process sequence, stock removal, and re-chucking influencing straightness and cylindricity. Grinding and honing correct errors machining cannot, reinforcing that machining distortion must be engineered out through an integrated machining–grinding–honing process, an area where Baxter Machine & Tool specializes for distortion-sensitive parts.