In-House Grinding vs. Outsourcing: Cost, Quality, and Risk

Executive Summary

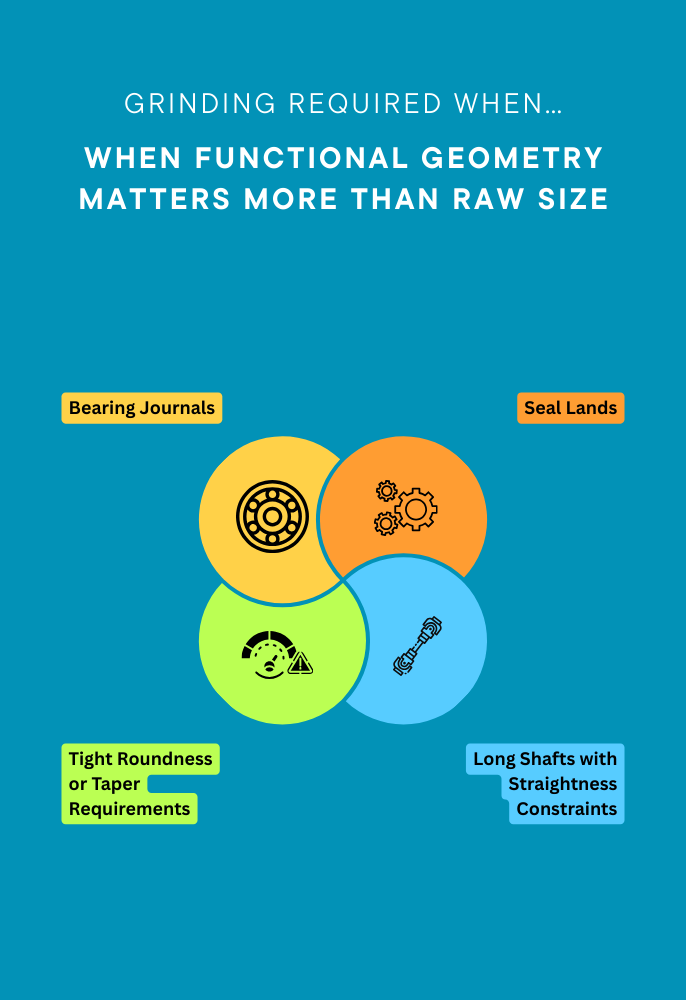

Grinding is not just a finishing step—it is a geometry-control operation.

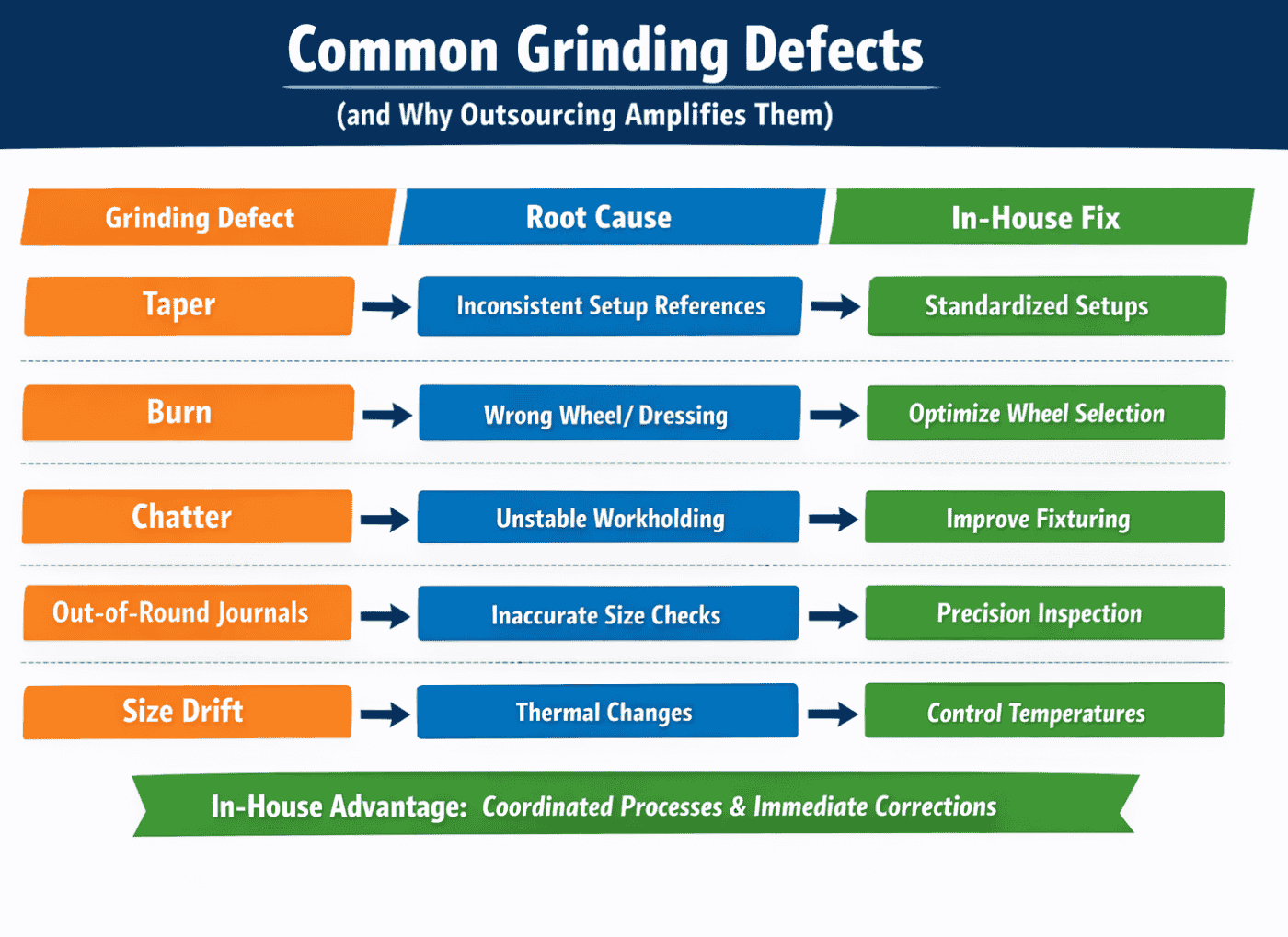

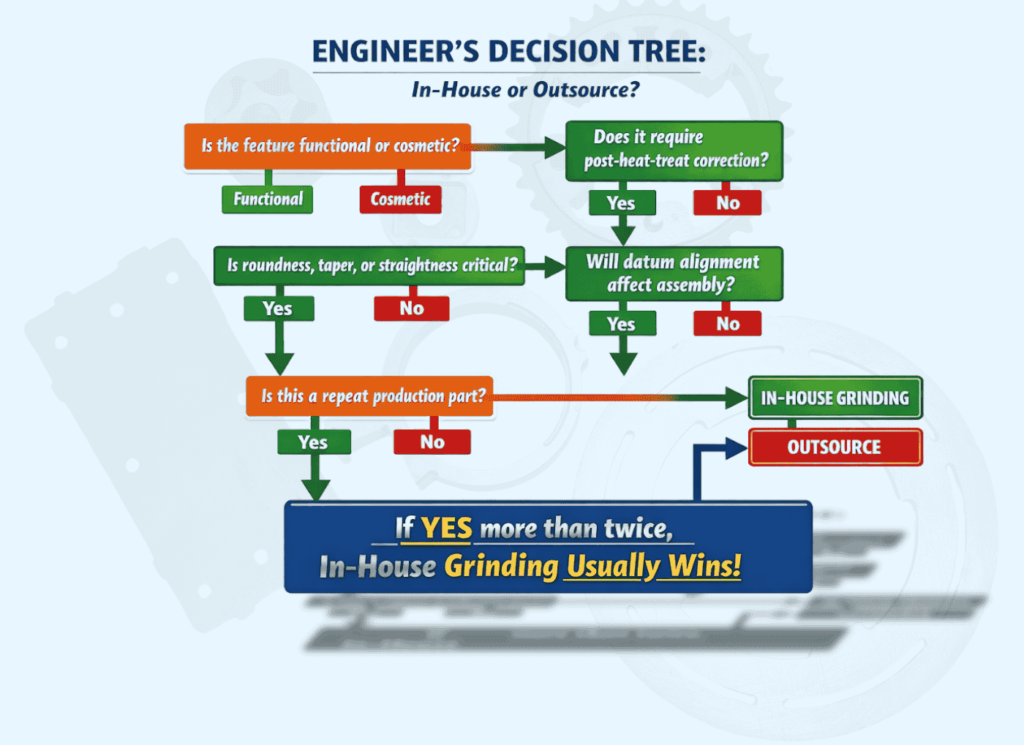

The decision to keep grinding in-house or outsource it affects tolerance capability, scrap risk, lead time, and total cost far more than most engineers expect.

Key takeaways:

- Grinding becomes mandatory when turning or milling can’t hold geometry reliably

- Outsourcing grinding adds hand-offs, datum changes, and schedule risk

- In-house grinding improves roundness, taper control, and repeatability

- Cost comparisons must include scrap, freight, and rework—not just piece price

Baxter perspective:

When turning, grinding, and honing are integrated under one roof, geometry stays controlled and variation stays contained.