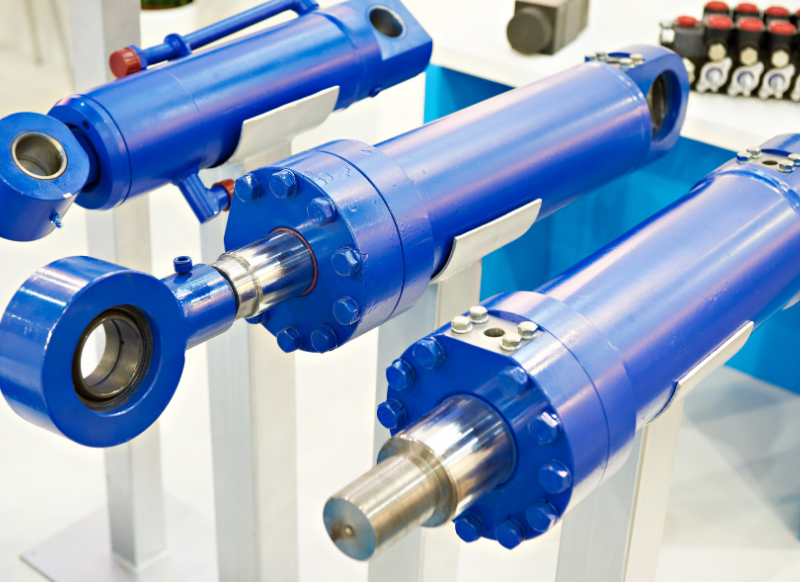

Machining for Hydraulic Systems: Bores, Spools, Sealing Surfaces & Functional Tolerances

Executive Summary

Hydraulic systems demand a different level of machining discipline than general mechanical parts.

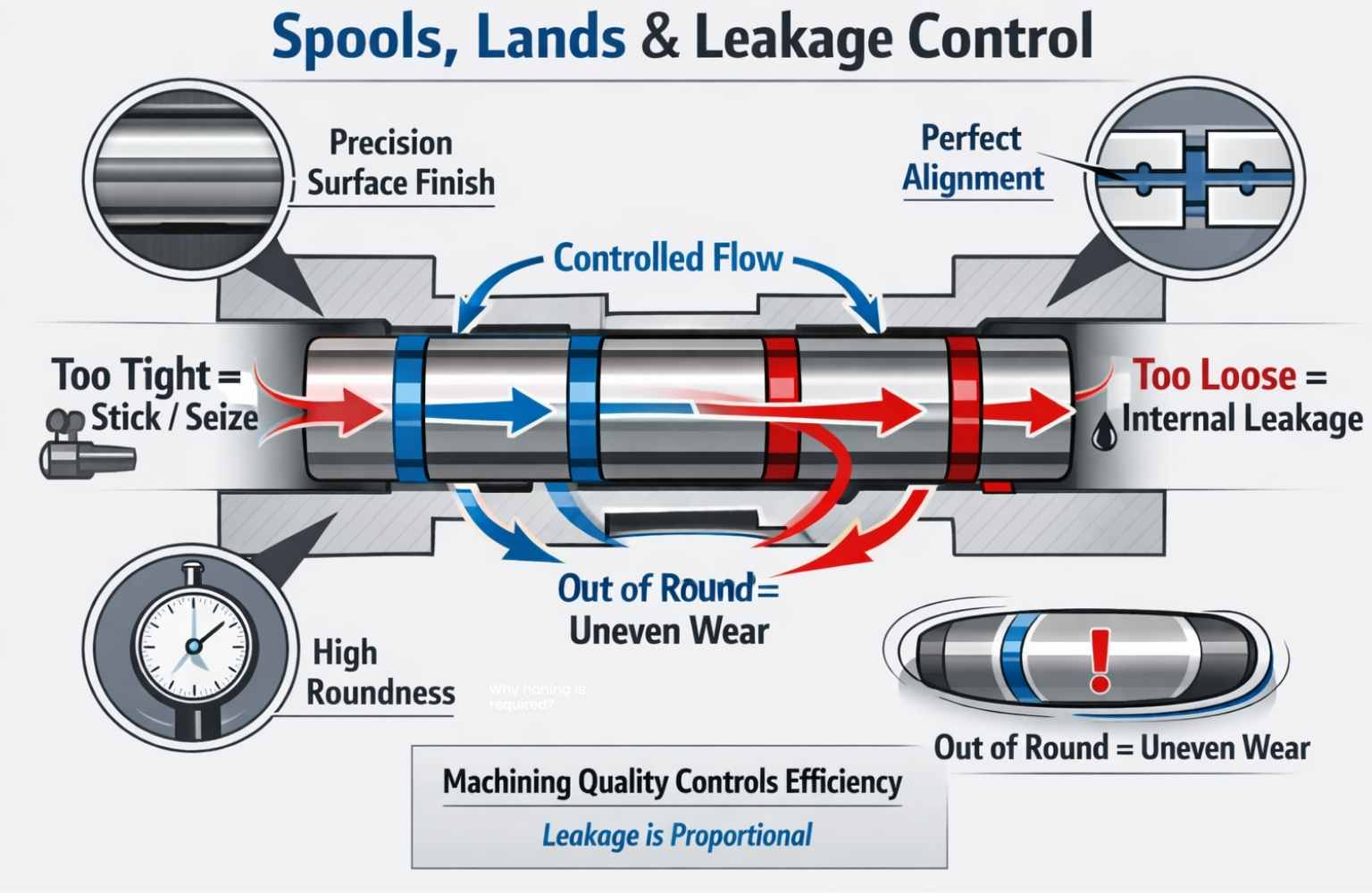

Small geometric errors that would be harmless elsewhere can cause leakage, stick-slip motion, pressure loss, or rapid wear in hydraulic assemblies.

Key points engineers should remember:

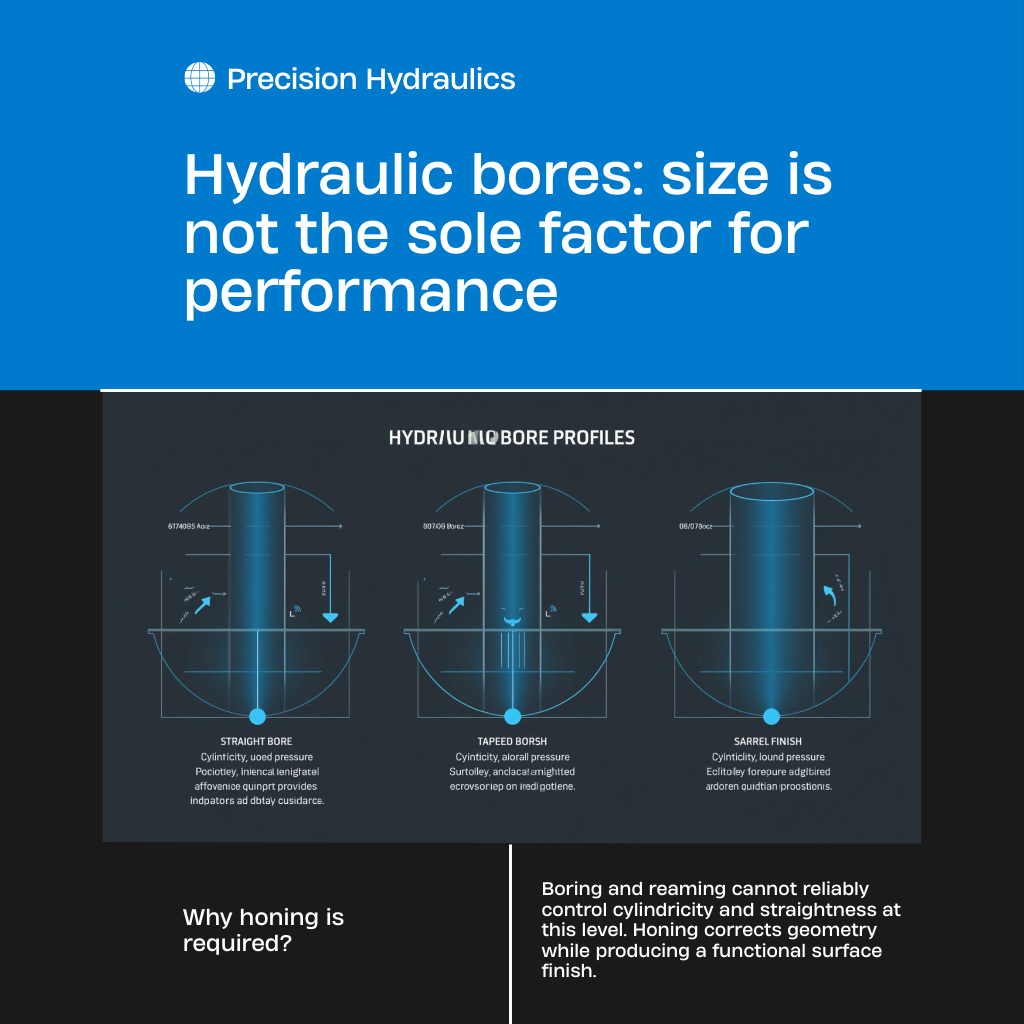

- Hydraulic performance depends on geometry + finish + tolerance, not size alone

- Bore straightness and cylindricity matter as much as diameter

- Spool and land tolerances control leakage and response

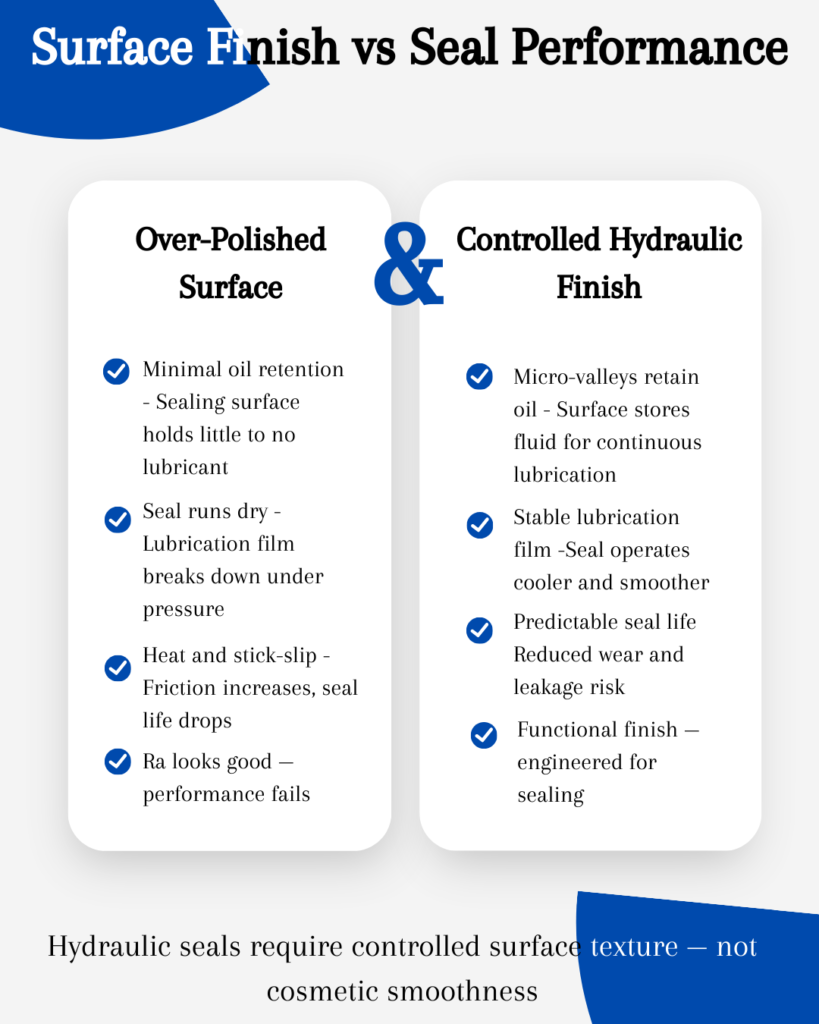

- Over-polishing sealing surfaces can be as harmful as rough finishes

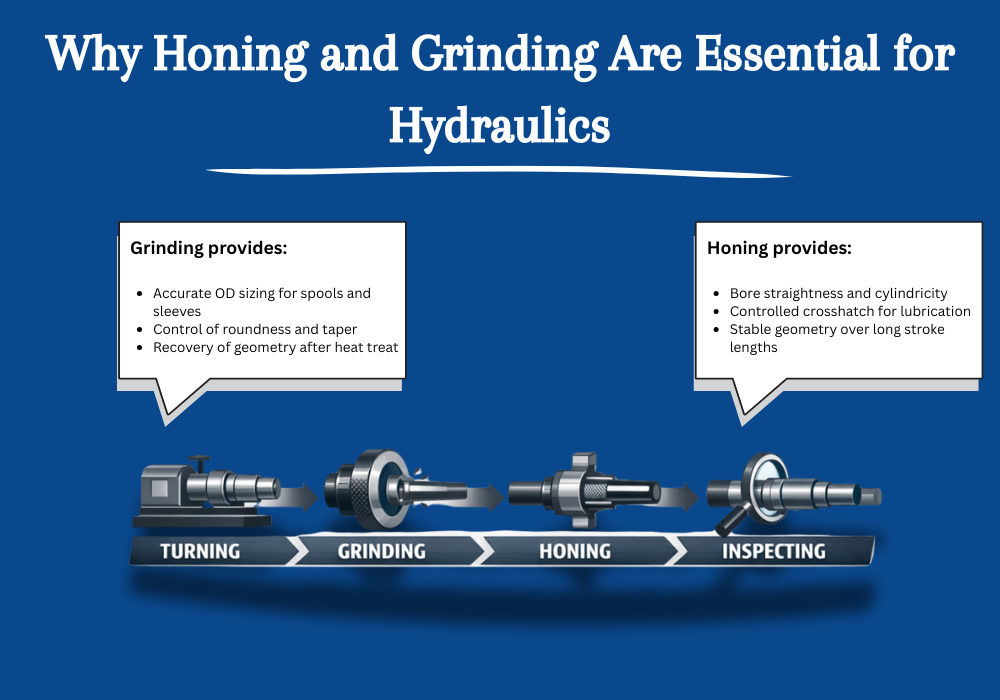

- Honing and grinding are often mandatory—not optional—for hydraulic parts

Baxter perspective:

Hydraulic machining succeeds when turning, grinding, honing, and metrology are integrated into one controlled process.

“`