CNC Tolerances Explained: How Tight Is Too Tight? A Practical Guide for Engineers

Executive Summary

Tighter tolerances are not always better. They increase cost, reduce yield, and limit supplier options—often without improving function.

Key points engineers should remember:

- Tolerance should follow function, not habit or legacy prints

- Every extra tenth adds cost exponentially, not linearly

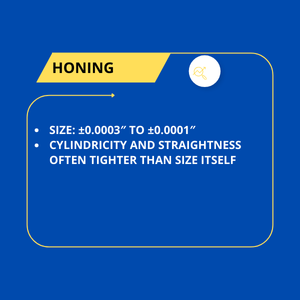

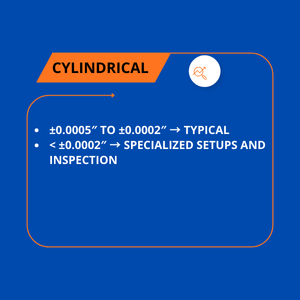

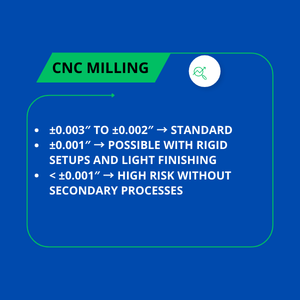

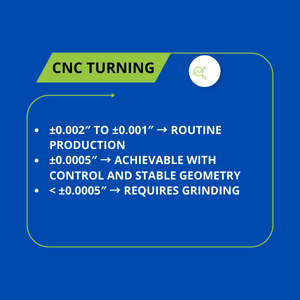

- Different processes (turning, milling, grinding, honing) have very different tolerance capabilities

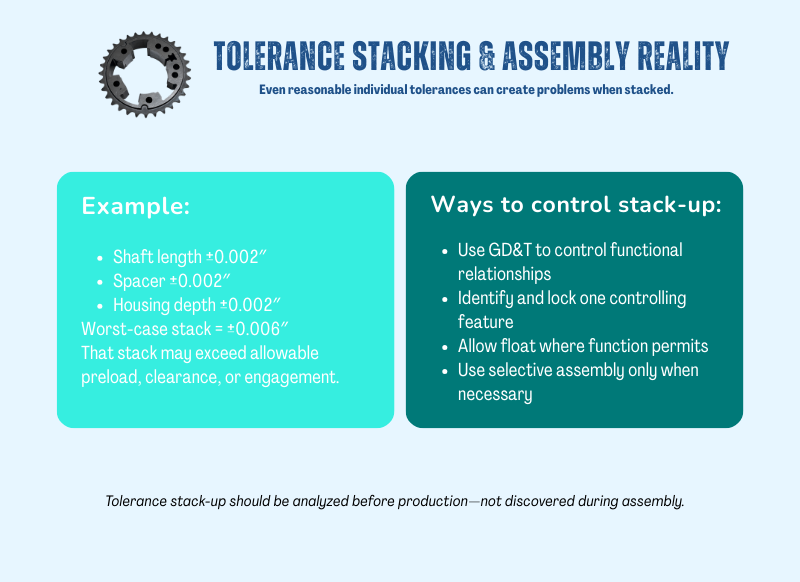

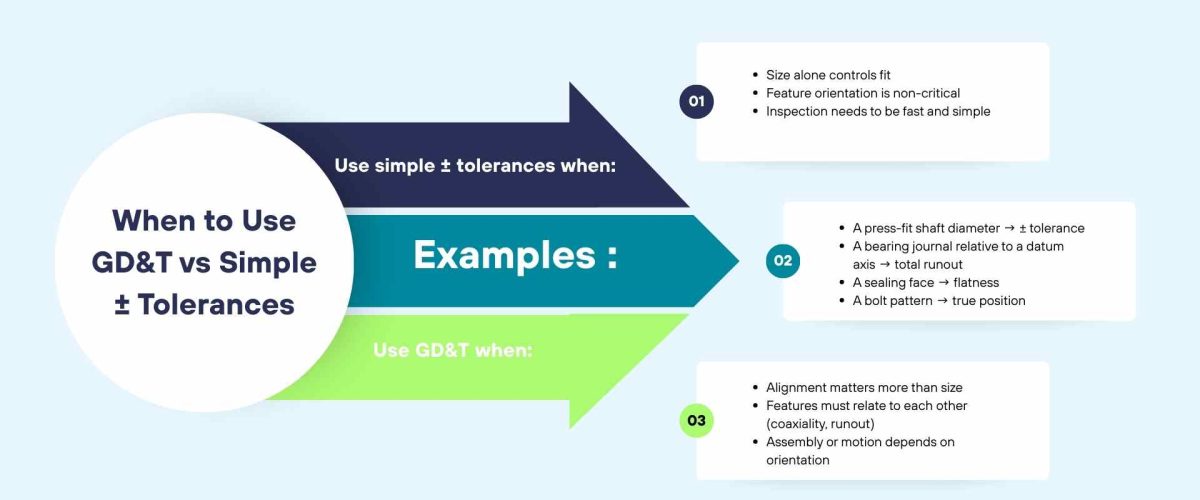

- GD&T is powerful—but only when used intentionally

- Surface finish, material, datum structure, and process order all influence achievable tolerance

Baxter perspective: Process-first quoting aligns tolerances with the right machining and finishing route so precision is achieved without unnecessary cost or risk.

Key insight:

Key insight: